Your specialist for renting, repairs and trading of deep

foundation equipment from the Ruhr Area.

Services

Rental park

Machinery & drilling equipment and much more

Trade

Everything you need

Service

Always a good decision

Information about our automatic casing drive adapter system Power Snap

No project is too small or too big

- 100%

The renting of drilling rigs, oscillators and casing systems has been part of our core business since the company was founded in 2002. Our customers, who operate in the field of specialised deep foundation and fountain construction, come from all over Europe.

Our planning team will be at your disposal to assist you with your enquiries relating to machinery and drilling equipment requirements on the job site. No project is too small or too big for our rental park and our network!

Our workshop team is your competent partner for overhaul and repair of special deep foundation equipment. We also perform customer-specific conversions and new designs in a professional manner.

Located in the middle of the Ruhr Area, the Oberhausen site not only has ideal transport accessibility, it also has the required crane capacity (16 to. + 10 to.) to ensure fast and safe loading.

Close cooperation with leading manufacturers, long-standing working experience and our continuous further development form is the professional basis for our work and your satisfaction.

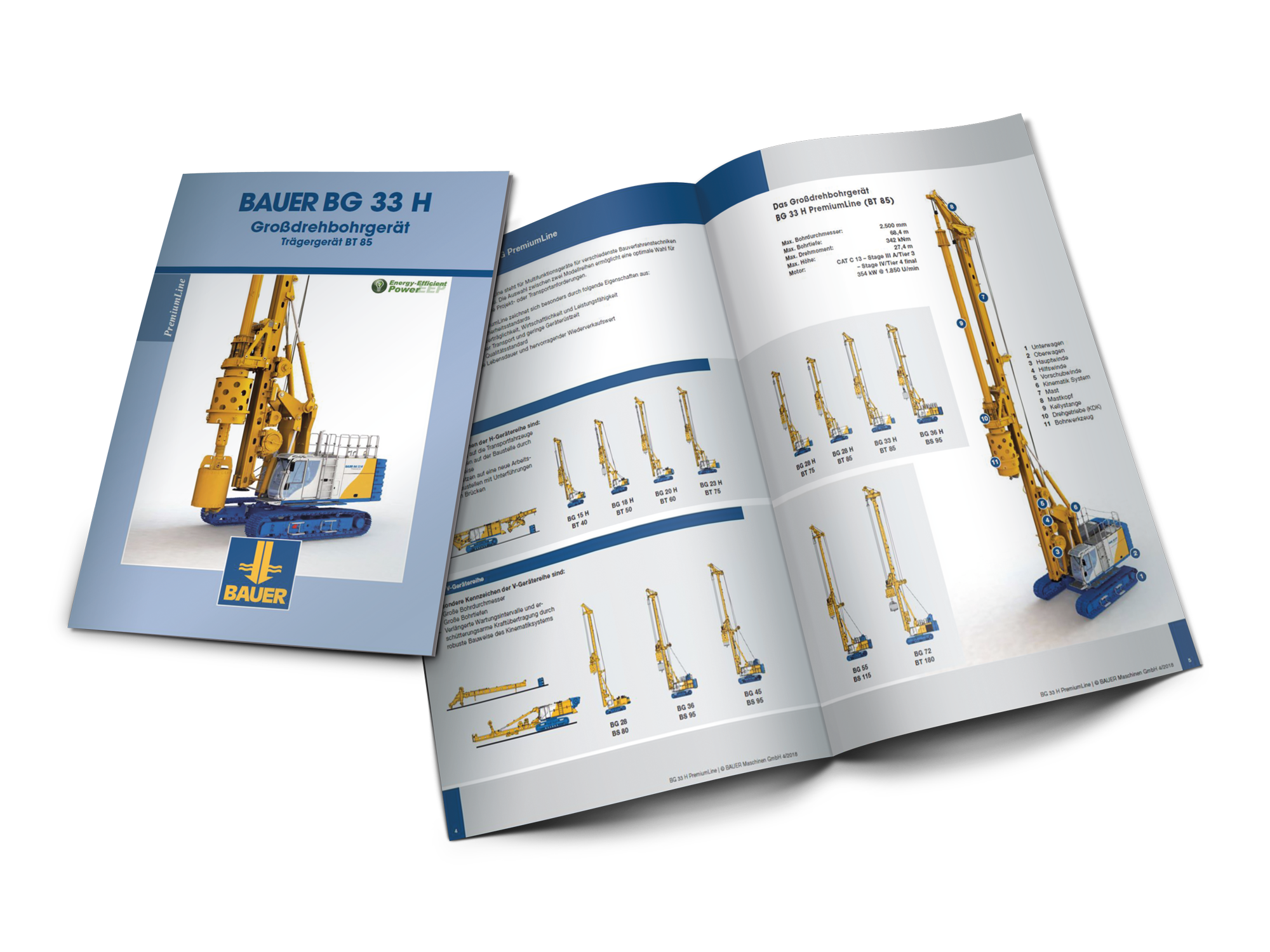

Rotary drilling equipment

- 100%

Along with special deep foundation equipment, you can also rent a drilling rig with an experienced machine operator. Our stock includes a Bauer BG 30 H as well as a Delmag RH 20. Exact specifications (transport dimensions, measurements) can be obtained from the respective data sheets.

casing & tools

- 100%

We have the relevant tools for individual diameters and our augers, drilling buckets as well as core barrel are supplied by leading manufacturers.

All tools have a 200 x 200 mm Kelly box and are designed for use on modern high-performance machinery. As standard, our adapter are equipped with cardan connections and have a stable deflector ring to protect the feed cable.

Oscillators & Hydraulic clamps

- 100%

If required, our rental park will supply you with Oscillators & Hydraulic clamps from Leffer. The oscillators are in KL design for connecting to a drilling rig. Operation is possible via the on-board hydraulic system of the drilling device or by means of a hydraulic aggregate. The drilling device is mechanically connected via the standard Leffer linkage system.

The following oscillators are available:

VRM 118 KL – reductions for Ø 1000/880/800/620

VRM 150 KL – reductions for Ø 1300/1180/1000/880

VRM 200 KL – reductions for Ø 1800/1500

The following retaining clamps are available:

SPA 100 – reductions for Ø 880/800/750/620

SPA 118 – reductions for Ø 1000/880/620

SPA 150 – reductions for Ø 1300

SPA 200 – reductions for Ø 1800

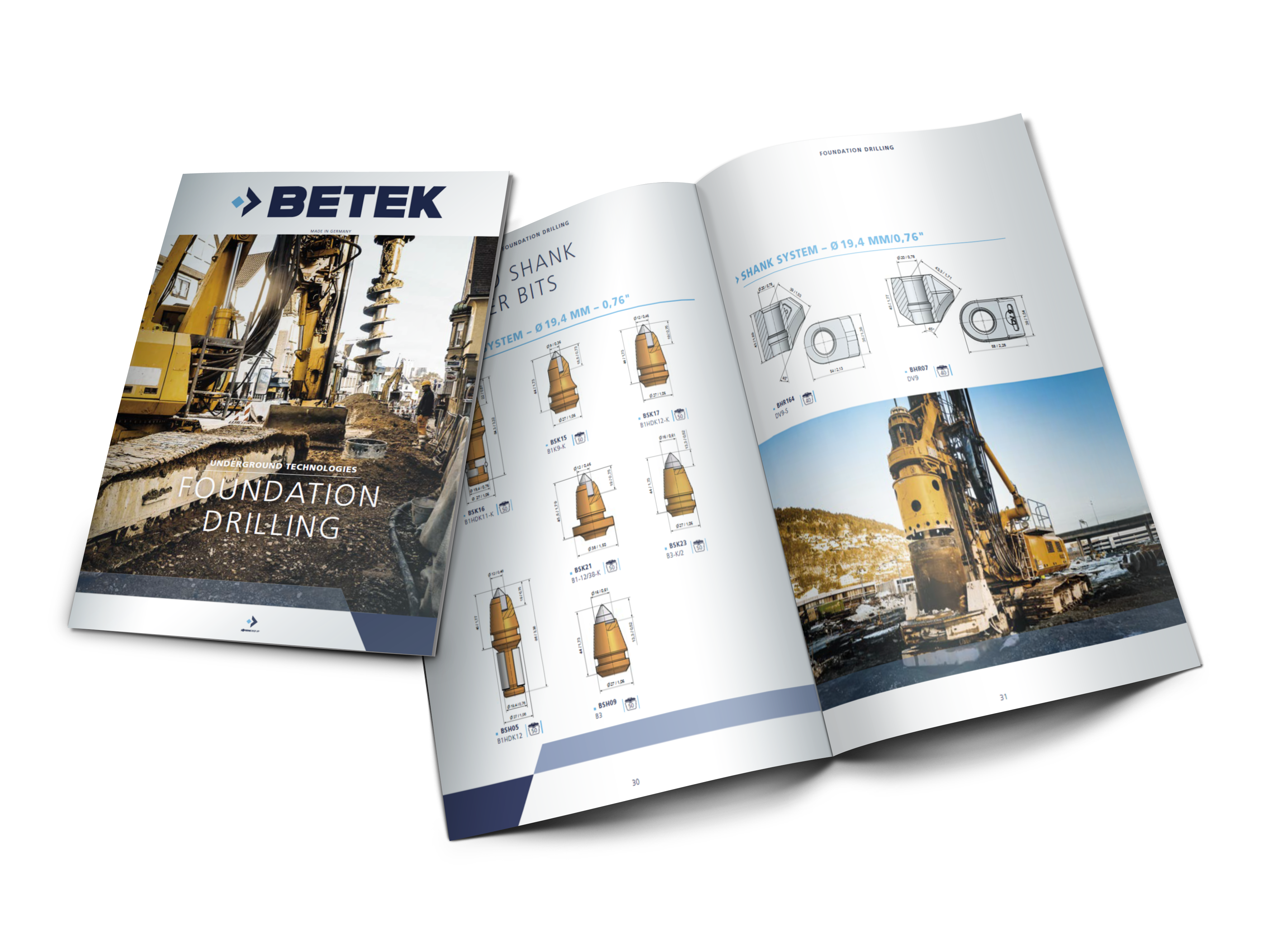

Trade

- 100%

We are very pleased to have taken over deliveries in November for the West/North-West area, which had previously been supplied by Klaus Melchior Industrievertretung GmbH.

You can obtain the complete Betek product portfolio from us. Just call us – we will be happy to advise you. Or meet us personally at our premises!

Service

- 100%

- Handing over and admission for oscillators and automatic casing drive adapter

- Partner for specific conversions and new designs

- Accessory repairs (e.g. kelly bars)

- Qualified welding and engineering work

- Delivery service for replacement and wear parts

automatic casing drive adapter system

- 100%

The idea

As a result of the constant rise in demand for automatic

casing drive adapter systems and the associated advantages

in the field of occupational safety, wear reduction and

efficient operation, we have decided to develop our

own automatic casing drive adapter system for rent.

The result is a robust and universal automatic

casing adapter, which can be fitted to all drilling

rigs with cardan connections. Further advantages of our automatic casing drive adapter Power Snap are:

- Immediate deployment without preliminary setup time- Immediate deployment without preliminary setup time

- Self-sufficient system

- Maintainability

- Fast replacement of wearing parts on the jobsite

- Battery life – 1 working day

- Emergency system

- Easy cleaning

On February 14th 2018, the patent with the European patent number 3163009 was

issued for the POWER SNAP automatic casing drive adapter system.

The automatic casing drive adapter Power Snap is a mechanically/electrically driven

hydraulic system.

Mechanism: automatic locking

Electrics: control

Hydraulics: unlocking

The GMT casing drive adapter is always locked mechanically/automatically when the adapter socket is fitted to the casing nipple through the spring pre-loaded locking

cylinder. Drilling thus always takes place over the locked bolts. Unlocking is carried out by

means of a filled hydraulic piston accumulator, which is controlled by an electrical radio

remote control. During unlocking, the radio remote control can only be activated by the

operator. Unlocking activates the sensors and switches on LED warning lights.

If all automatic locking bolts are in a locked state, the sensors switch off the LED warning

lights.

The POWER SNAP is self-sufficient, i.e. the hydraulic energy required for the piston

accumulator is generated by fitting the adapter on the casing using two thrust

rods with pump cylinders. Power is supplied by means of chargeable 24V batteries.

Contact

- 100%

Office

Andreas Domagalla

Tel.: +49 (0) 209 – 380 791 39

Karsten Bolien

Tel.: +49 (0) 209 – 380 666 55

Michael Grzeszick

Tel.: +49 (0) 209 – 380 380 43

Fax: +49 (0) 209 – 380 985 08

Heinz Hermann Lepkojis

Mobil: +49 (0) 157 – 71464589

You have the right at any time to revoke your permission to establish contact with future effect. In this case, your personal data that has been stored will be immediately deleted. After processing your enquiry, any further personal data will also be deleted.

Further information on data privacy and the handling of personal data can be found in our data protection declaration.

Sitemap

- 100%